K2 SKI

GRAPHIC DESIGN

PRODUCT DESIGN // DIRECTION, DESIGN, & PRODUCTION

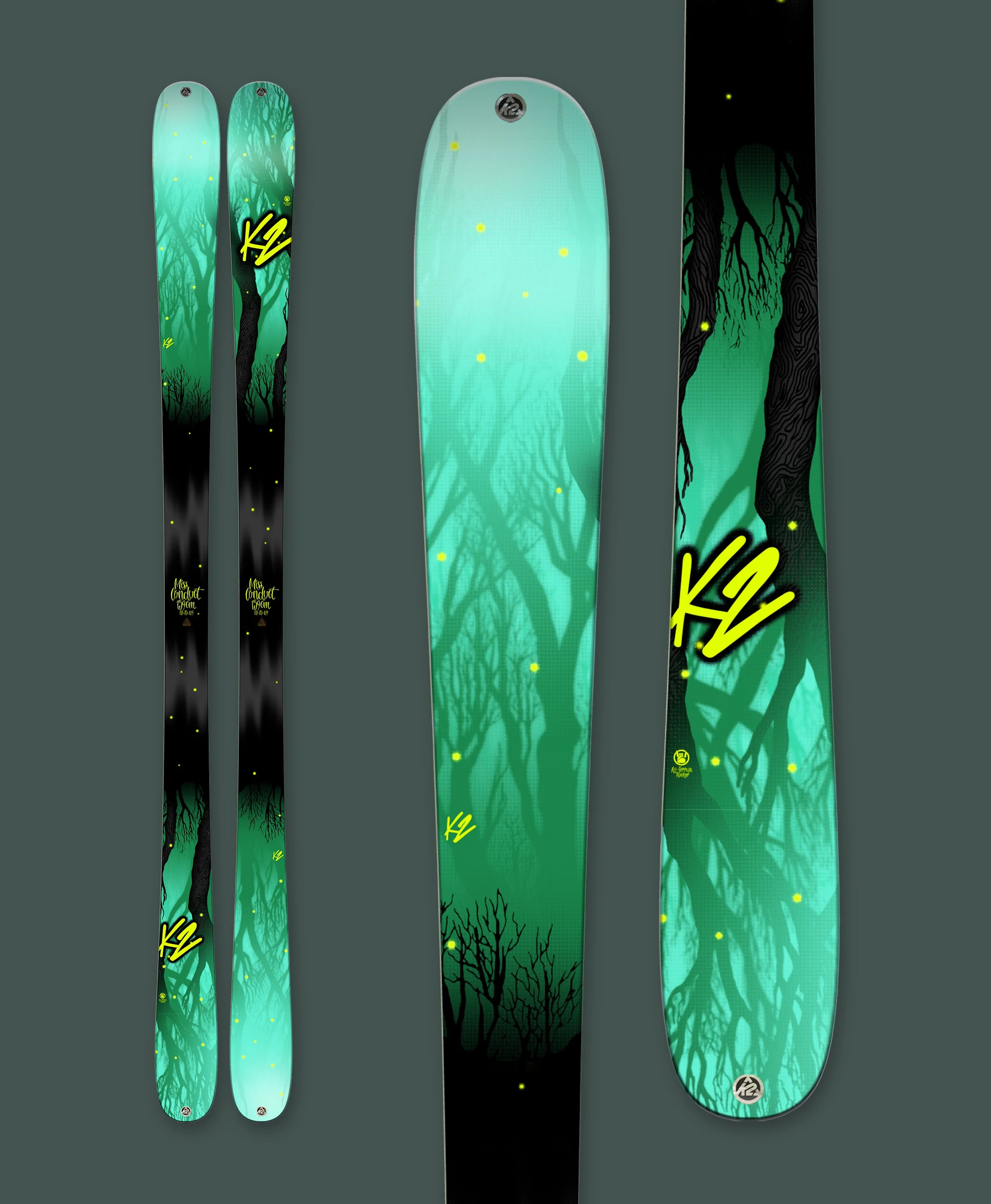

Designing ski graphics over multiple seasons gave me a unique experience in creating literal artwork for products. Each ski model targets specific customer groups, so each ski graphic needs to embody its attitude, which should resonate with that customer's lifestyle and cultural trends. Capturing these ideas was always a study in current trends and markets. Still, it needed to evolve to meet the future product release schedule — essentially designing one to two years out in the present.

When I began designing for K2, I emphasized bringing my illustrative talents to the team. Many of these ski graphics started with literal pen and paper illustrations, converted to digital images, placed in a ski template, and colored up according to each model's allowed color count. Some skis had just three colors permitted for production; others had up to 9. Logos and model spec lock-ups are always needed to communicate specific attributes for each ski. I learned much about color separation and production artwork through my work with K2 Ski. I worked with the in-house production team to sample the graphics before sending them to production in Asia.

I designed skis for every category, including all-mountain, freeride, freestyle, backcountry, and youth. I also worked directly with K2’s roster of professional ski athletes to develop graphics specific to their model of choice.

Designing skis took a lot of cross-departmental collaboration between design engineers, marketing, sales, and production.

PRODUCT DEVELOPMENT

RECON & LUV BOOT COLLECTION // PRODUCT DEVELOPMENT

From 2016 to 2017, I helped K2 develop a new line of ski boots for all-mountain skiers – The K2 Recon (men’s) and Luv (women’s). This project was a collaborative effort between the product development team, sales, and marketing. I worked under creative direction to contribute ideation and industrial design concepts to parts of the boot like the buckle shape, liner designs, and even the outsole tread patterns. I also helped work towards the final color, material, and graphics packages used for these models.

K2 SKIS PRODUCT CATALOG // DESIGN & PRODUCTION

MEDIA PRODUCTION

2016 K2 SKI TEAM VIDEO // PRODUCTION

While I was part of the marketing team at K2, We would frequently assist in production projects that focused on the team of pro skiers. I was fortunate to have been a part of this production, working alongside photographers and videographers to help concept, capture, and create the opening sequence of this team video.

The idea was to showcase K2’s strong brand history in the sport by showing our NEW 2016 ski model next to our OLD ski model from the late 80s. Although both ski models shared the same graphic, the technology used to create the new model ski and the capabilities it offered skiers were vastly different than that of its predecessor. Regardless, the idea we wanted to show was that skiing was fun back then and is still just as fun now. It doesn’t matter what kind of equipment you’re on, as long as you’re on a hill sliding around, you’re having a good time.

We brought the team up to Mt Hood where we had some special jump features made for the team to use on a private part of that glacier that was off-limits to anyone not involved with the shoot. This was one of the only times I was able to experience the entire K2 Freestyle Ski team together in one place. It was truly epic. Many of the skiers were hesitant to clip into the old ski models, for fear of injury or just looking silly, but once they tried them out, they realized just how much fun they could have on these old pieces of K2 brand history.

PRODUCT DEVELOPMENT

AND DESIGN

K2 TRIO INLINE SKATE // PRODUCT DEVELOPMENT, DESIGN & PRODUCTION

I had been working with K2 Skate, mainly helping with design comps and product testing. I grew up skating and had an intricate knowledge of the customer, product category, construction and performance, and the overall market. When the product development team expressed a need to create a new skate within their Lifestyle category, they also asked me to help them develop it. This was one of my childhood dreams come true. I got to design a skate model from scratch.

This was a multi-stage design process which required cross functional collaboration. I worked closely with the team of design engineers, manufacturers, and other athletes to develop this product. I also was in close communication with the European market, since Inline Skate was the biggest category, generating the most revenue for K2 in Europe. I had been studying footwear design and had a pulse on what kind of developments were being made in the lifestyle and fashion footwear worlds, specifically pertaining to materials, applications, and production. This in-depth knowledge of footwear trends, and inline skate performance provided a strong foundation for the ideation process.

I drew up ideas of what the skate could look like, how its lines and curves would flow around the base, and what features it could include. Every concept I put on paper had a physical performance purpose and functionality paired with an aesthetic to match the skates intended user. I must have produced close to fifty individual sketches, constantly evolving in shape and design, until the team agreed to move forward with an agreed upon favorite.

The sketches were turned into technical digitla drawings, complete with production specs like colors, materials, and finishes. K2 had an extensive fabrics library from a number of suppliers and manufacturers. I also attended materials shows and expos where suppliers from all over the world would share their latest innovations and best selling technologies. Through careful consideration, I was able to find the best choices suitable for this skate.

I designed a graphics package for this skate to work with the new "infinity" shaped frame design. This frame was unique and new to K2, so I wanted to utilize its shape to create a motif that would be expanded into the overall graphic design ecosystem of the skate itself.

I spent some time traveling to and from various production facilities throughout asia — Hong Kong & Shenzhen in China ,and around Bangkok in Thailand — to oversee the production of this skate. There were so many different manufacturing facilities all producing different components for these skates. There was an aluminum machining plant that made the frames, a Poly Urethane Wheel manufacturer who made the wheels to spec, and printed the artwork on them, and the upper, or boot manufacturer who created the patterns and completed the stitching to produce the "shoe" of the skate. Making sure all of these components matched the designs I had developed was an integral part of the design process.

During the development of the K2 Trip inline skate, I was also designing and developing the complete K2 Inline skate product line. I helped oversee production for all models within the line.

We completed production and the skate launched, becoming the best selling model in K2's Inline Skate category. I'm extremely grateful for the experience to have designed this product through all of the collaborative efforts with teams all over the world.

PRODUCT DESIGN

K2 HELMETS & GOGGLES // PRODUCT DESIGN & PRODUCTION

I got to have a lot of fun with the goggle designs for K2. The fashionable accessory line allowed me to experiment and play around with colors and print designs I would probably not get to create. From designing logo badges and straps to picking out lens colors and mirrors from Zeiss, the lens supplier, designing these goggles was enjoyable.

The hardest part of promoting these goggles was capturing them on camera in a studio. We had to build a specially designed light tunnel for these to be photographed in so that the lenses did not catch any weird reflections from the studio in which they were being photographed. This process posed many challenges, mainly being time. We decided to go complete digital rendering with google images. These renders were created well before any 3D rendering programs were included and accessible through the Adobe Creative Suite. Creating these renders from scratch challenged me in new ways and forced me to pay close attention to details like shading, depth, and reflection on digitally rendered images.

Because our sales team would present these accessories to potential buyers and dealers as packages, I designed the helmets and goggles to merchandise together through shared colorways and patterns. Helmet design and production typically consisted of choosing Pantone colors and creating graphics and logo lock-ups that would be printed or applied to the shell. Additionally, there was a need to design the patterns and choose the fabrics used in the liners and ear pads.

PRODUCT DESIGN

K2 SKI BOOTS // PRODUCT DESIGN & PRODUCTION

I designed the Spyre Series ski boots for K2 using the same methodology and processes I used for inline skate design — trend analysis, product colorway compositions, graphic design, materials selection, sampling, and production.

To design this model, I took a non-traditional approach to pattern and graphic implementation. I created a texture pattern that was used throughout the boot and applied it strategically to areas that made the most sense. I printed the entire interior liner, a component that is rarely seen. Then I found an 80% opacity dark plastic with gold flakes that would be used in the injection molding process to create the shell. This transparent plastic allowed the pattern on the interior liner to show through to the outside of the boot.

This boot won the award for "best women's all-mountain ski boot" at the 2016 SIA Show.